Revolutionary mobile home from LEMKI Robotix: the future of 3D printing with composites. The Ukrainian-German company LEMKI Robotix and Iscale3D has made a revolutionary breakthrough in large-scale 3D printing by creating DISCOVER 3D, a mobile home printed from an eco-friendly composite material consisting of recycled polypropylene (7400 bottles) w...

Photography

LEMKI Robotix

By embracing carbon fiber reinforcement in your 3D printing projects, you're not just enhancing the durability and performance of your creations—you're unlocking a whole new world of possibilities!

Written by

Jane Macaballug

The Bambu Lab Automatic Material System (AMS) is a game-changer for 3D printing enthusiasts and professionals alike. Automating material management drastically reduces manual interventions, minimizes waste, and enhances overall productivity.

Written by

Jane Macaballug

As the cost of construction materials increases, developers and builders are trying to find ways to address the housing shortage. One solution would be 3D printing. This tech provides a quicker and cheaper construction phase, with the potential of using recycled materials.

Written by

Aaron Chambell

The latest project from the architectural design firm Studio RAP utilises its own bespoke, custom-built 3D printing technology to transform a boutique facade on Amsterdam’s P.C. Hooftstraat. According to Studio RAP, The Ceramic House reshapes architectural expression by seamlessly blending tradition and innovation, reintroducing bespoke details to...

Project name

Ceramic House

Architecture firm

Studio RAP

Location

P.C. Hooftstraat, Amsterdam, Netherlands

Photography

Studio RAP / Riccardo De Vecchi

Principal architect

Wessel van Beerendonk & Lucas ter Hall, Team Studio RAP

Collaborators

Royal Tichelaar

Interior design

Gietermans & Van Dijk

Supervision

Wessels Zeist (VolkerWessels)

Tools used

Rhino, Grasshopper

Construction

Wessels Zeist (VolkerWessels), Royal Tichelaar

Material

Bespoke Ceramics, 3d ceramic printed panels.

Client

Warenar Real Estate

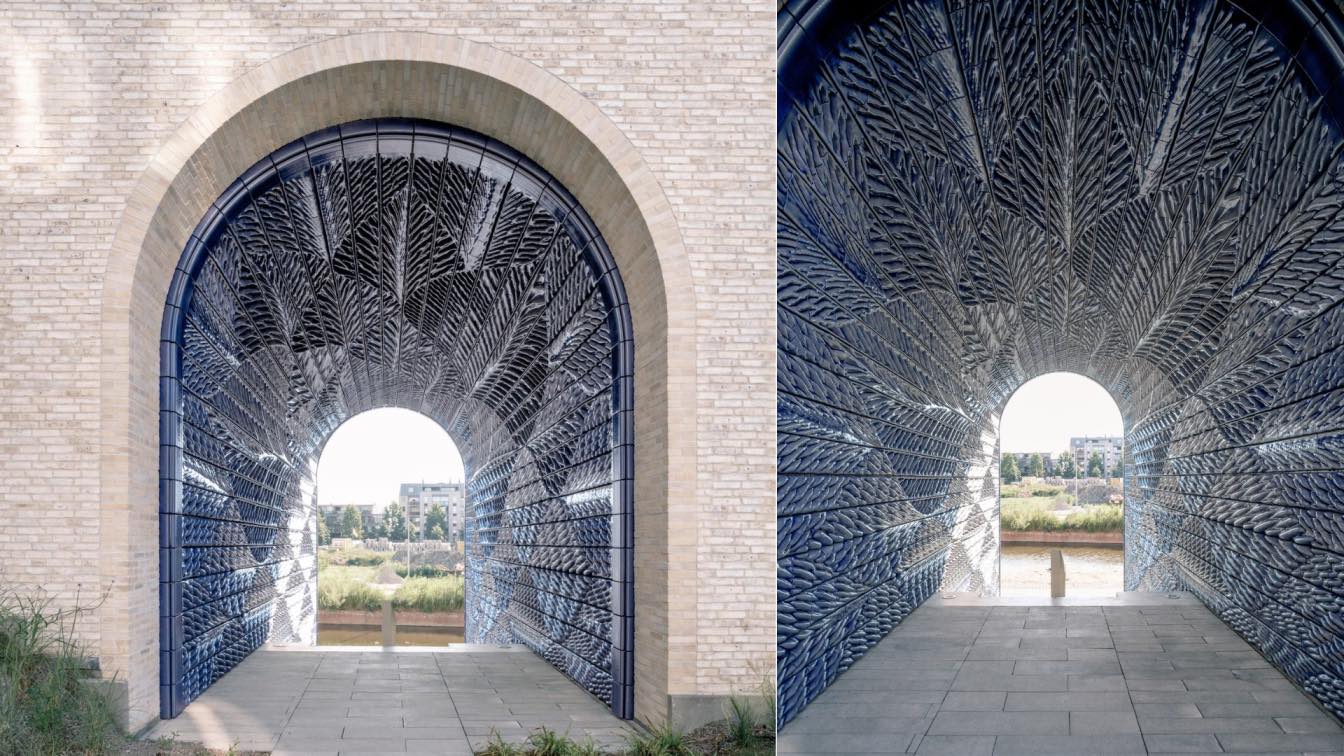

New Delft Blue is a pioneering project in the historic Dutch city Delft, designed and 3D printed by Studio RAP. This project reinterprets the world-famous decorative qualities and design vocabulary of Delft Blue porcelain.

Project name

New Delft Blue

Architecture firm

Studio RAP

Location

Delft, The Netherlands

Photography

Riccardo De Vecchi

Principal architect

Studio RAP, Lucas ter Hall & Wessel van Beerendonk

Design team

Lucas ter Hall, Wessel van Beerendonk

Collaborators

VY Architects (Architect PoortMeesters)

Site area

Gate A 5x12 (60 m²), Gate B 5x11 (55 m²)

Tools used

Rhinoceros 3D, Grasshopper

Construction

Kooistra Geveltechniek

Material

3D ceramic printing by Studio RAP & Firing and glazing by Tichelaar B.V.

Client

BPD (Bouwfonds Property Development), Ballast Nedam

Typology

Gates, Artwork, Facade

American University of Sharjah (AUS) researcher and Professor in Civil Engineering Dr. Adil Al-Tamimi has been researching the use of robotics in 3D printing of concrete in construction.

Written by

American University of Sharjah (AUS)

Photography

Dr. Adil Al-Tamimi

The design of Flowin’, the new pedestrian bridge for Moganshan Town over the Fuxi River, begins with a careful analysis of the chosen project site. The generation of the form was guided by a series of parameters: the relationship with the anthropic and natural context, the tectonics, and its structural behaviour.

Project name

Flowin’ Footbridge

Architecture firm

Barberio Colella Architetti + Angelo Figliola

Location

Moganshan Town, China

Tools used

Rhinoceros 3D, Grasshopper, Karamba, V-ray

Principal architect

Maurizio Barberio, Micaela Colella

Design team

Maurizio Barberio, Micaela Colella, Angelo Figliola

Collaborators

Zhenghui Chen

Visualization

Barberio Colella Architetti

Client

Deqing County Cultural Tourism Development Group Co., Ltd.

Typology

Infrastructure › Footbridge