There are many ways to create models and prototypes. One of the popular ways is laser cutting and engraving. Many people have used lasers to create exciting and eye-catching designs. But before we look at their key benefits, let’s examine what laser engraving and cutting are.

What is Laser Engraving and Laser Cutting

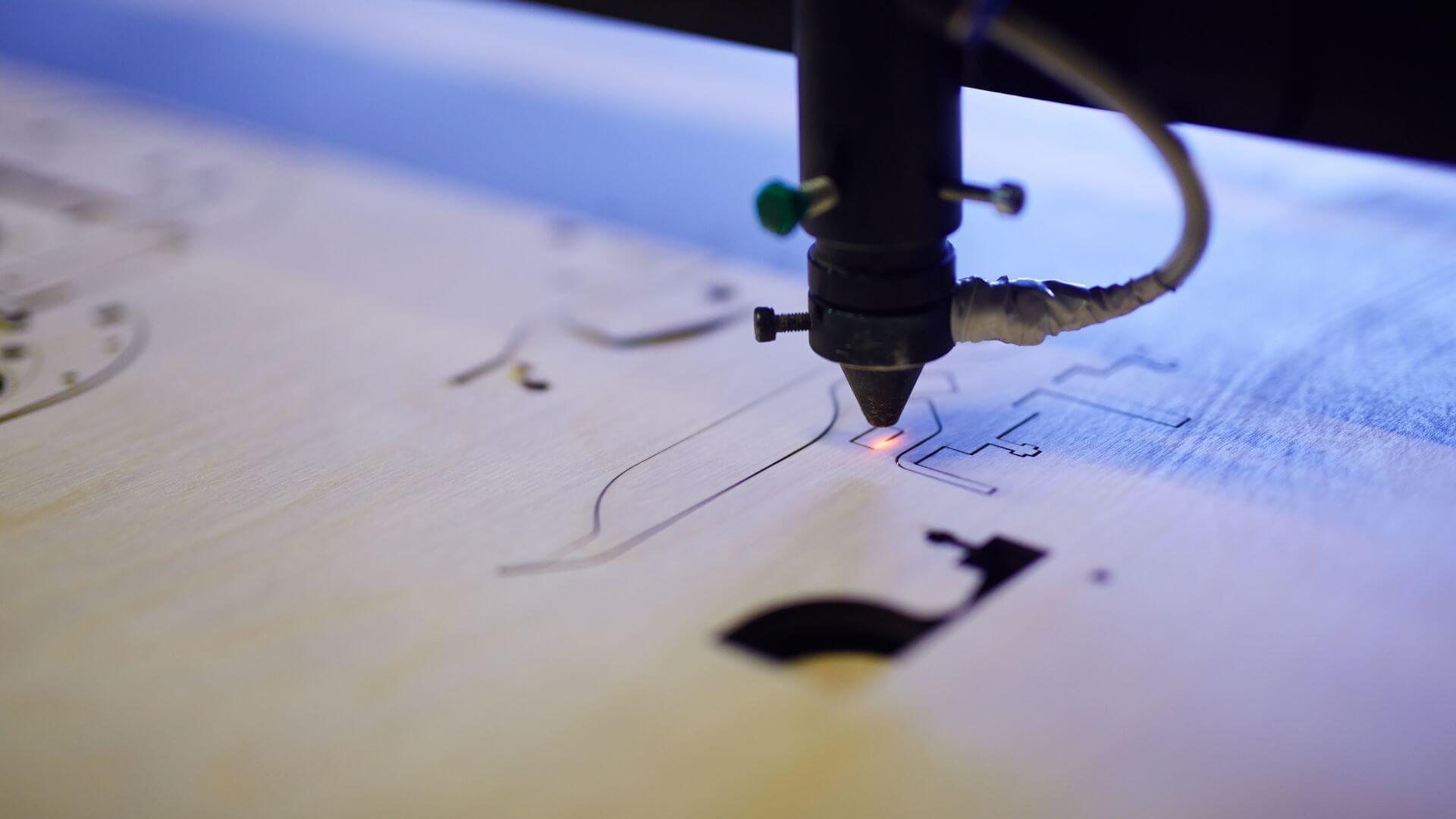

Laser engraving and laser cutting both use a laser to alter the surface of a material. Laser engraving uses the laser to create an image or text on the material's surface. In contrast, laser cutting uses the laser to cut through the material to create the desired model or prototype. High Precision Fiber Lasers are often used in both applications to achieve exceptional detail and consistency, especially when working with metals and industrial-grade materials.

Both processes can be used on various materials, including wood, glass, metal, and plastics. Laser engraving is typically used for creating 3D logos or other product images, while laser cutting is often used for prototyping or manufacturing.

Having looked at what laser engraving and laser cutting are, let’s now look at the advantages of creating a model with laser cutting and laser engraving.

5 Benefits of Creating 3D Models With Laser Cutting and Engraving

1) It is a Very Precise Process

The precision of the cuts and engravings is unmatched. The files used to direct the laser cutter or engraver are usually accurate as they are created in design software, and all the details are prepared beforehand. Hence you're sure that the measurements and overall look of the final design will be as intended. As long as you have chosen the best laser engraver and all the other factors are kept constant, you can cut and engrave with incredible accuracy, and there is no room for errors.

2) It Saves Time and Money

Another benefit of using lasers for cutting and engraving in creating models is their work speed. Lasers can produce results much faster than traditional methods such as sawing or carving. These lasers save time and money when producing many components.

Additionally, these processes are particularly well-suited for handling delicate materials, such as thin plastics and metals; conventional cutting tools would damage that, saving costs down the road. They can also be used to create detailed designs and patterns that would be very difficult to produce using traditional methods.

3) There is Less Material Wasted

Lasers produce little waste when creating models, meaning less material is wasted in manufacturing. This is because laser engraving and cutting start with a computer file that tells the laser where to engrave or cut, and there is no trial and error as the laser produces the material that needs to be removed. These materials are also released in small amounts at a time, ensuring an optimized use of resources.

Such efficiency is paramount for industries like aerospace systems and components manufacturing. Considering the high-grade and often expensive materials these manufacturers use, particularly when dealing with intricate aerospace components, any reduction in waste can lead to significant cost savings. By adopting laser cutting and engraving methods, aerospace component manufacturers can optimize their production processes, reducing both costs and environmental impact.

4) They Offer a High Degree of Flexibility

Laser engraving and cutting machines offer a high degree of flexibility for creating models and prototypes. With these machines, it is possible to create intricate designs with high precision in various materials. This flexibility makes them an ideal tool for prototyping and testing new product designs. In addition to their flexibility in creating models and prototypes, laser engraving machines themselves are highly versatile. They come in various sizes and power capacities, ranging from desktop laser machines suitable for small-scale projects to large industrial ones used for mass production. Furthermore, laser engraving machines can be used to engrave and cut a wide range of materials, including metals, plastics, wood, leather, and textiles. Moreover, laser engraving machines can be easily programmed to create highly detailed and intricate designs with great accuracy, making them ideal tools for both personal and commercial use.

In addition, laser engraving and cutting machines are relatively fast and efficient, meaning that they can be used to create large numbers of prototypes in a short period.

5) Compatibility With a Wide Variety of Materials

Laser cutting and laser engraving are compatible with a wide range of materials. Metals, plastics, glass, wood, and even fabric can all be cut or engraved using laser technology. So, creating models through these technologies will make it easier to produce them using different materials, and one won't be limited by the materials supported. This gives 3D designers and manufacturers much flexibility when choosing a suitable material for their projects.

Conclusion

Laser cutting and engraving is an exciting technology that can help you create various models and prototypes. The five advantages we’ve highlighted should give you a good starting point for understanding the potential benefits of this process, and it could be the perfect choice for your next project.